For centuries, granite has been a fundamental component of construction and design, as it is one of the most durable and graceful natural stones. The granite manufacturing process is a meticulous fusion of expert craftsmanship and state-of-the-art technology. This article explores the complete voyage of granite, from the extraction of raw blocks from the earth to the preparation of polished slabs for installation.

Granite Quarrying: Raw Block Extraction

Granite Manufacturing Process journey starts at the quarry location. Techniques intended to maintain the blocks’ size and integrity are used when extracting granite from quarries.

Drilling and Jet Piercing

Large drill machines bore precise holes into granite deposits, while jet piercers use flame jets to cut through the stone. This process helps in loosening the blocks with minimum breakage.

Wire Saw Cutting

Diamond wire saws are then used to separate the massive granite blocks from the bedrock. This method offers high precision and ensures a clean cut, reducing waste and damage.

2. Transportation and Handling of Granite Blocks

Once extracted, granite blocks are loaded onto heavy-duty trucks or railcars. Special care is taken to secure and cushion the blocks to prevent any damage during transportation to the processing facility.

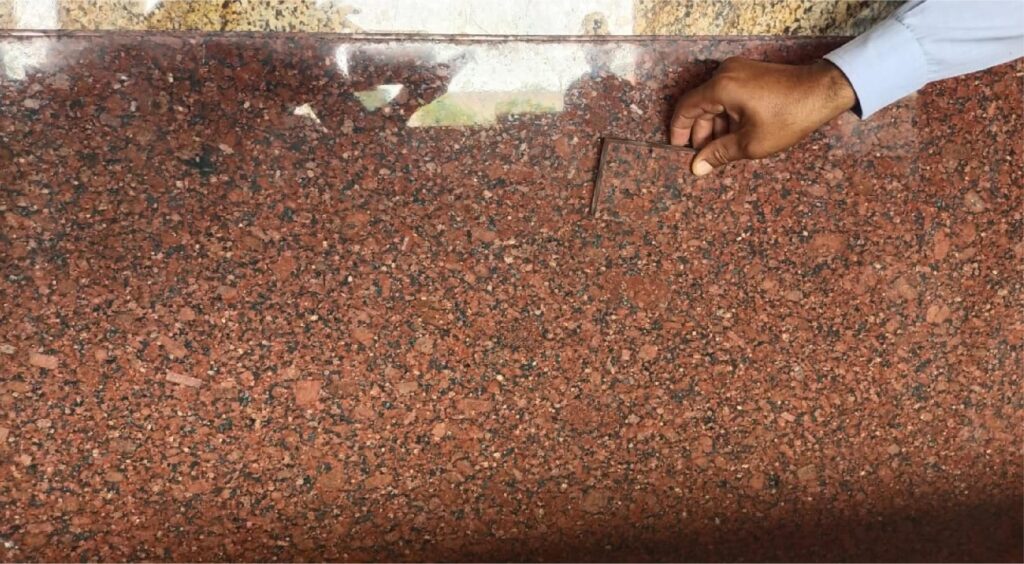

3. Inspection and Quality Grading

At the manufacturing plant, each granite block undergoes a thorough inspection to evaluate:

- Color consistency

- Veining and patterns

- Presence of cracks or impurities

- Overall structural soundness

Blocks that meet high standards move forward to the next phase. Others are either rejected or used for lower-grade applications.

- Making the first cut from block to slab

The authorized granite blocks are subsequently transformed into thick slabs by primary cutting equipment. Diamond Wire Saws and Gang Saws

These devices cut through stone with amazing precision using high-tension steel blades inlaid with diamonds. Depending on the block’s size and hardness, this operation may take several hours.

5. Surface Treatment – Honing and Polishing

Once the slabs are cut, they undergo surface treatment to enhance their appearance and texture.

Honing

Honing removes the roughness from the surface, giving the granite a smooth, matte finish. This is preferred for floors and outdoor applications where slip-resistance is important.

Polishing

For countertops and decorative pieces, slabs go through a series of polishing heads embedded with abrasives. The result is a mirror-like finish that reflects light and showcases the stone’s natural beauty

6. Resin Application and Strengthening

Granite slabs often contain natural micro-fissures or pinholes. A resin coating is applied to:

- Fill imperfections

- Improve strength

- Enhance gloss

The slabs are placed in vacuum chambers so the resin penetrates deep into the stone. After curing, the slabs are re-polished for uniformity.

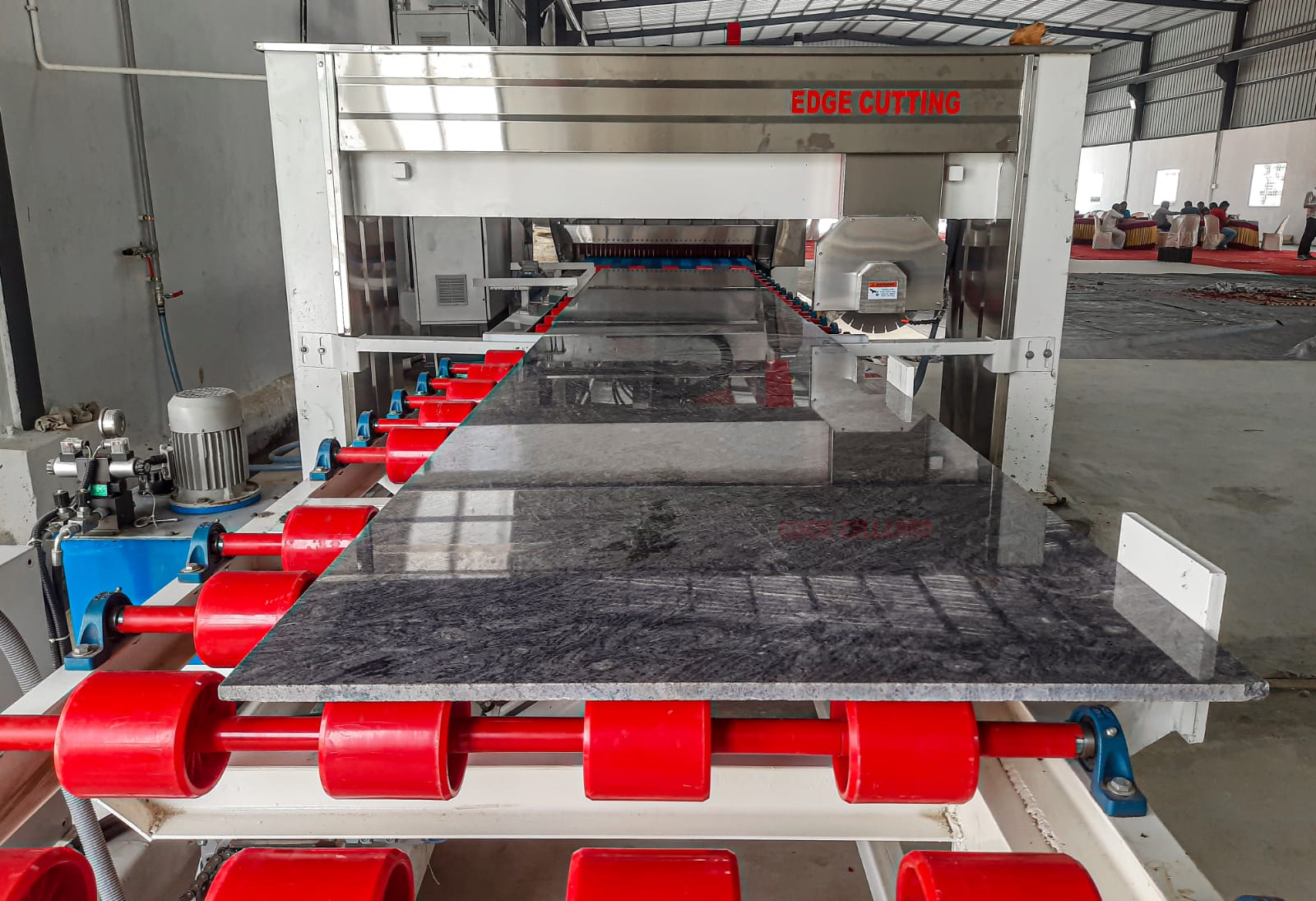

7. Edge Cutting and Shaping

After calibration, slabs are cut into custom sizes and shapes using:

- Bridge saws

- CNC routers

- Water jets

8. Final Inspection and Quality Assurance

Each processed slab undergoes a final quality check where experts verify:

- Polish consistency

- Thickness uniformity

- Color and pattern matching

- Dimensional accuracy

Only the slabs that meet strict quality parameters are marked ready for distribution.

10. Packaging and Shipping

Granite slabs are carefully packed using wooden crates, foam padding, and moisture-resistant covers to prevent damage during transit. GPS-tracked logistics ensure on-time and safe delivery to distributors, retailers, or directly to customers.

Once Granite Manufacturing Process completed, granite is ready for use in a wide range of applications:

- Kitchen countertops

- Bathroom vanities

- Flooring tiles

- Wall cladding

- Fireplace surrounds

- Garden pathways

- Memorials and monuments

In conclusion

A number of extremely precise procedures are used in the granite manufacturing process to turn natural rock into surfaces that are stunning, long-lasting, and useful. From quarrying to the last installation, each stage demonstrates how technology and nature can coexist. The industry produces high-quality granite products that endure over time by using contemporary techniques and strict quality control measures.

Leave a Comment