One of the most durable and visually appealing natural stones is granite. To bring raw stone to polished perfection, it undergoes several stages of manufacturing. Here are the Step-by-Step Granite Tiles Manufacturing Process.

Extraction of granite from quarries

The journey of granite began deep within the earth. Granite quarries typically extract large blocks using wire saws, diamond belt saws, or blasting methods. A 40-ton block can be considered massive. A manufacturing plant receives the granite blocks after they have been extracted. The quality of each block is checked before it is moved on to the next stage.

Further processing of the block with block dressing

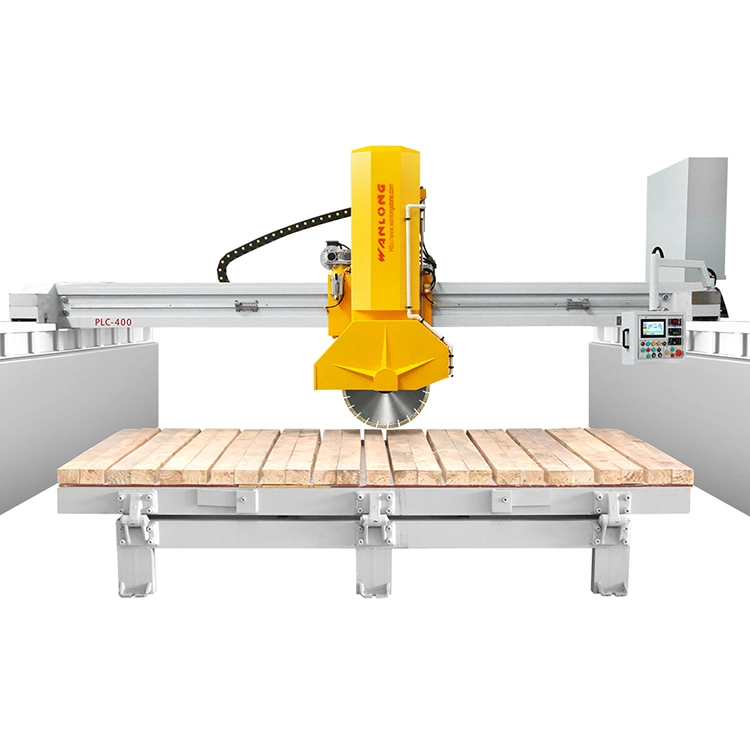

The blocks are then cut into manageable sizes in the factory. A dressing is the result of this process. Gang saws or circular saws are used to trim rough edges. In order to prepare dressed blocks, the desired slab thickness must be taken into consideration. For further slicing, this step ensures uniformity.

Granite slabs are thinned at this stage by block cutting machines. A diamond wire saw or gang saw is widely used. Depending on the size of the block, sawing can take hours. Air circulates between these slabs by stacking spacers between them. To polish them, they must dry completely after washing.

Grinding and polishing of surfaces

Granite shines here because of its beauty. To smooth the surface of slabs, abrasives are used. Sheen is gradually enhanced by polishing machines with multiple heads. 60 grit to 3000 grit is the range of polishing grades. Gloss is improved with higher grit. A resin treatment is applied to minor cracks and holes.

Application of epoxy for surface reinforcement

Epoxy resin is often applied to the slab surface. This helps fill natural pores and micro cracks. It also enhances shine and structural strength. The slab is then baked in an oven to cure the resin. This process is critical to ensure lasting quality.

Granite slabs are now cut to custom dimensions. Edge cutting machines and CNC routers are used. Clients may request various edge profiles like beveled, bullnose, or ogee. Precision is key to perfect fit in applications like kitchen countertops or flooring.

Quality inspection and finishing

Each slab passes through a strict quality inspection. Technicians check for color consistency, cracks, polish finish, and thickness. Slabs that meet quality standards are labeled and packed. Final touches like an anti-slip coating or flamed texture are applied if needed.

Finished granite slabs are packed using wooden crates, foam, and plastic wrap. This protects the surface during shipping. Shipping is domestically or internationally. Proper documentation ensures smooth logistics and delivery.

Sustainable Granite Manufacturing Practices

Many manufacturers now adopt eco-friendly practices. These include water recycling systems, low-emission machinery, and responsible quarrying. Dust control systems and slurry management are also part of modern granite processing.

Granite manufacturing is a blend of nature and technology. Every stage — from quarrying to polishing — requires precision, labor, and quality control. Granite’s durability, aesthetic appeal, and variety make it a top choice for interiors and exteriors. Understanding the manufacturing steps helps us appreciate the effort behind every beautiful granite slab.